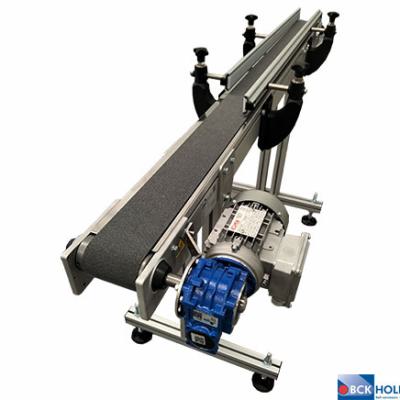

Stainless steel belt conveyors

A belt conveyor with a stainless steel frame is often used in moist areas and/or for products where stainless steel is required. The BCK stainless steel belt conveyors are available in types BS60, BS80 and BS113.

Due to the choice of materials and the hygienic design, the stainless steel belt conveyors are suitable for the food industry (HACCP environment), the pharmaceutical industry and the chemical industry, among others. Good cleanability is taken into account in the design phase by standard or optional application of:

Partly due to the modular concept, it is possible to make various types of stainless steel belt conveyors of any type, such as a flat stainless steel belt conveyor, elevator, elevating conveyor, hopper conveyor, curved conveyor, incline conveyor or Z-conveyor.

- a folding feed roller

- a folding side guide

- a detachable funnel

- a drum motor

- an FDA and/or HACCP approved belt material

- an easily removable strap

- an open frame for good accessibility during cleaning

Partly due to the modular concept, it is possible to make various types of stainless steel belt conveyors of any type, such as a flat stainless steel belt conveyor, elevator, elevating conveyor, hopper conveyor, curved conveyor, incline conveyor or Z-conveyor.

Belt conveyor type BS60

The BS60 belt conveyor is a hygienic transport solution. The folding reversing roller and the stainless steel frame make it easy to clean. This hygienic belt conveyor with stainless steel frame owes its name to the standard diameter of the conveyor roller, which is about 60 mm.

Do you require a drum motor? Then choose the BS80 or BS113.

Environment: Dry to moist and clean to slightly dirty

Load: max. 200 kg

Speed: Max. 75 m/min

Roller diameter: Standard Ø60 mm (Ø16 knife edge)

Belt conveyor type BS80

The BS80 belt conveyor is the more robust version of the BS60 belt conveyor and can be equipped with a drum motor. With a roller diameter of 80 mm and larger bearings, it can carry more weight. The BS80 performs best when used in dry to humid and clean to slightly dirty environments.

Environment: Dry to moist and clean to slightly dirty

Load: Max. 300 kg

Speed: Max. 125 m/min

Roller diameter: Standard Ø80 mm (Ø16 knife edge)

Belt conveyor type BS113

The BS113 belt conveyor is the heaviest stainless steel belt conveyor in its class. This robust hygienic belt conveyor with a high stainless steel frame owes its name to the standard diameter of the conveyor roller, which is about 113 mm. The BS113 performs best when used in dry to humid and clean to slightly dirty environments.