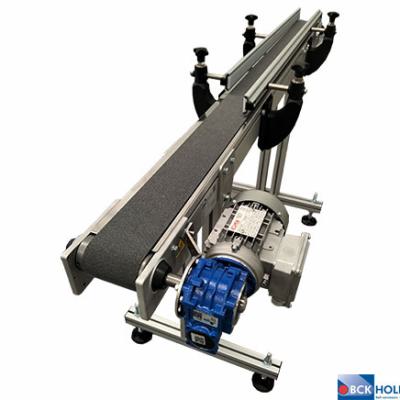

Aluminum belt conveyors

If there is no humid environment or stainless steel is not required, a belt conveyor with an aluminium frame can be applied. BCK aluminum belt conveyors are available in types N60, N60+ and N114.

The basic frame is made of aluminum construction profiles. These profiles are designed from experiences of our users. The T-slots in the profiles are designed so that standard fasteners can be tilted in from the side. This means that various components (such as side guides or photocells) can easily be fitted to the frame by us or the customer after delivery. The T-slots can also be sealed later with a plastic sealing profile.

By standardisation, the aluminium belt conveyors are available in various widths. Partly because of the modular concept, it is possible to make various types of aluminium belt conveyors, such as a flat aluminium belt conveyor, elevator, feeder conveyor, bunker conveyor, bend conveyor, vertical curved belt conveyor or Z conveyor.

Belt conveyor type N60

Environment: Dry and clean to slightly polluted

Load: max. 200 kg

Speed: Max. 75 m/min

Roller diameter: Standard Ø60 mm (Ø16 knife edge / Ø80 drum motor)

Belt conveyor type N60+

Environment: Dry and clean to slightly polluted

Suitable for highly dynamic applications

Load: Max. 300 kg

Speed: Max. 125 m/min

Roller diameter: Standard Ø80 mm