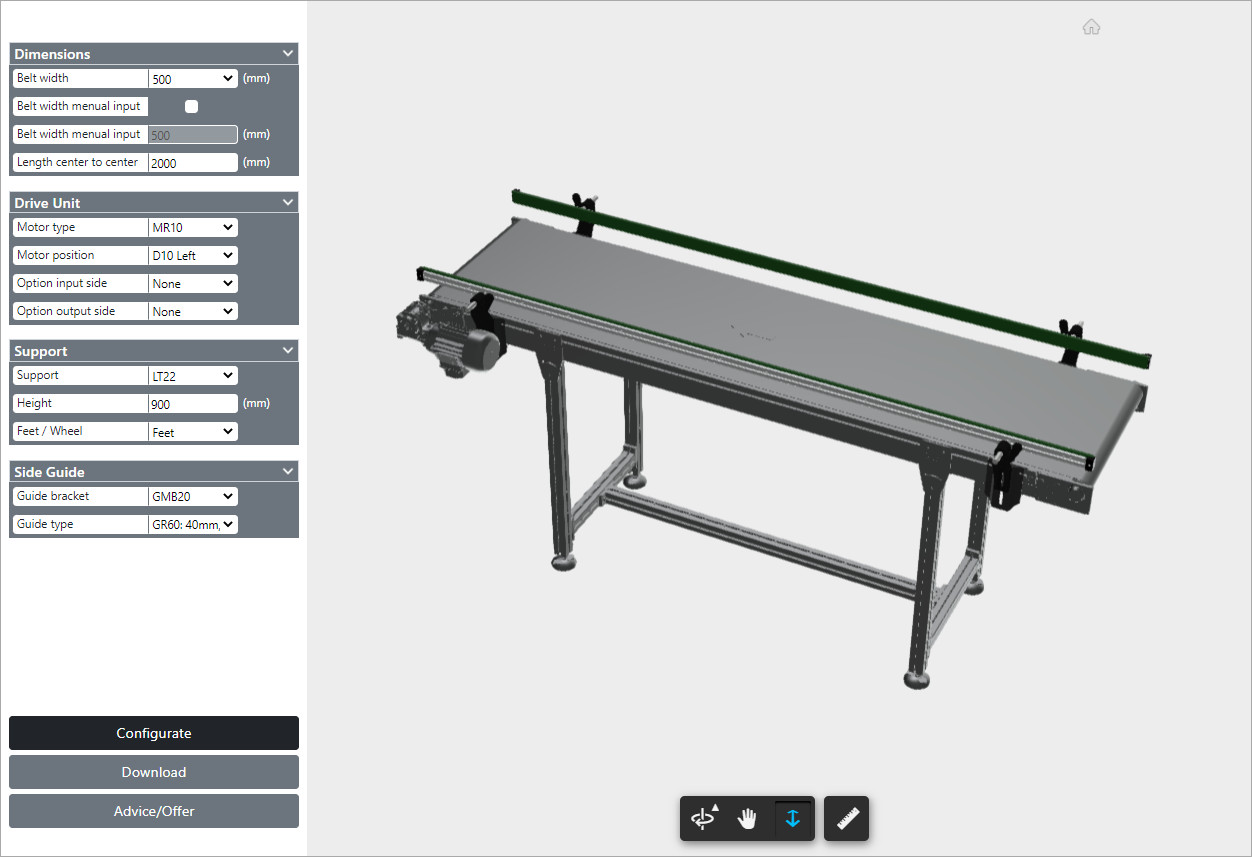

Belt conveyor type N60

The N60 belt conveyor is the most economical belt conveyor in its class. This belt conveyor with an aluminium frame gets its name from the standard diameter of the conveyor roller, which is about 60 mm. The N60 performs best when used in a dry and clean to slightly polluted environment.

Terms of application

Environment: Dry and clean to slightly polluted

Load: Max. 200 kg

Speed: Max. 75 m/min

Roller diameter: Standard Ø60 mm (Ø16 knife edge / Ø80 drum motor)

The N60 belt conveyor has its own profile and is designed from experiences of our users. The T-slots in the N60 profile are designed so that standard fasteners can be tilted in from the side. This means that various components (such as side guides or photocells) can easily be fitted to the frame by us or the customer after delivery. The T-slots can also be sealed later with a plastic sealing profile.

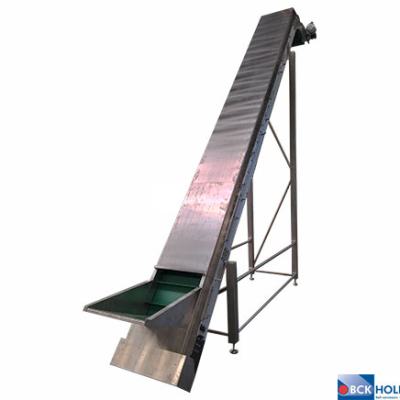

By standardisation, the belt conveyors type N60 are available in various widths. Partly because of the modular concept, it is possible to make various versions such as a flat aluminium conveyor, elevator, feeding belt conveyor, bunker conveyor, vertical curved belt or Z conveyor.

Technical specifications

- Basic: Aluminium frame with stainless steel sliding plate;

- Transport direction: Unidirectional;

- Belt width: 70/100/150/200/250/300/350/400/450/500/600/700/800/900/1000/1200 mm;

- Length: 350 - 25,000 mm;

- Roller diameter: Ø60 mm (standard) / Ø16 mm (fixed or rolling kife edge) / Ø80 mm (drum motor);

- Drive type: (in)direct end drive / (in)direct central drive;

- Motor position: Combination of Left/Right and Pulling/Pushing;

- Speed: Max. 75 m/min (depending on version);

- Type of rollers: Standard aluminium hard anodised rollers;

- Motor gearbox: Standard 3x230/400V, 50 Hz, IP55;

- Belt material: Choice of various brands, materials, frictions and colours;

- Base frame fitted with a positive and/or negative vertical curve (25°/30°/45°);

- Base frame equipped with extra intermediate beams;

- Drive shaft fitted with a customer-specific shaft journal;

- Other motor gearbox configuration/brand or drum motor;

- Stainless steel transfer rollers Ø16 mm;

- Drive roller fitted with various types of coverings (PVC sleeve or laminop) for increased grip;

- Various types of belt accessories such as flights, corrugated edges or a mechanical connector;

- Steering V-belt underneath the belt;

- Stainless steel package: axles, bearings and fasteners are made of stainless steel;

- Standard, telescopic or heavy supports/legs;

- Supports/legs on adjustable feet or castors with brake;

- Side guide (fixed or adjustable in green, black, blue or white);

- Electric control.

Online 3D configurator