Mini-conveyors

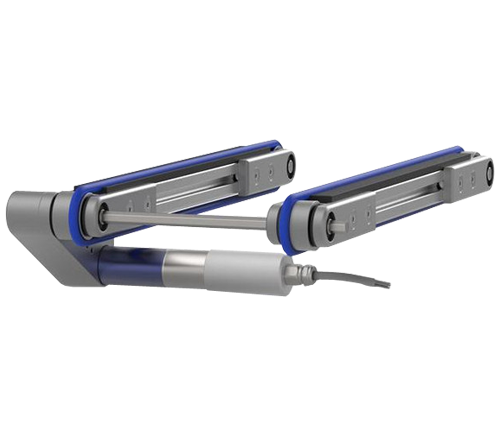

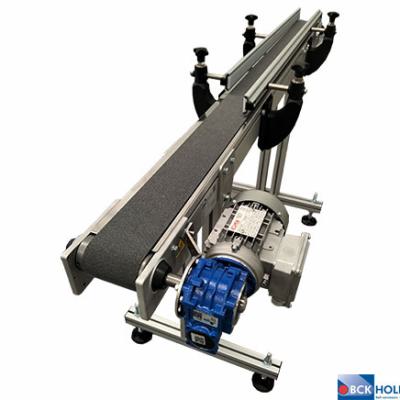

The mini-conveyor completes BCK's range by providing a solution for very small belt conveyors as well. These mini-conveyors, from the Vetter Kleinförderbänder brand, are mainly used where space is limited and the product is small and light.

These features are mainly found in the following systems:

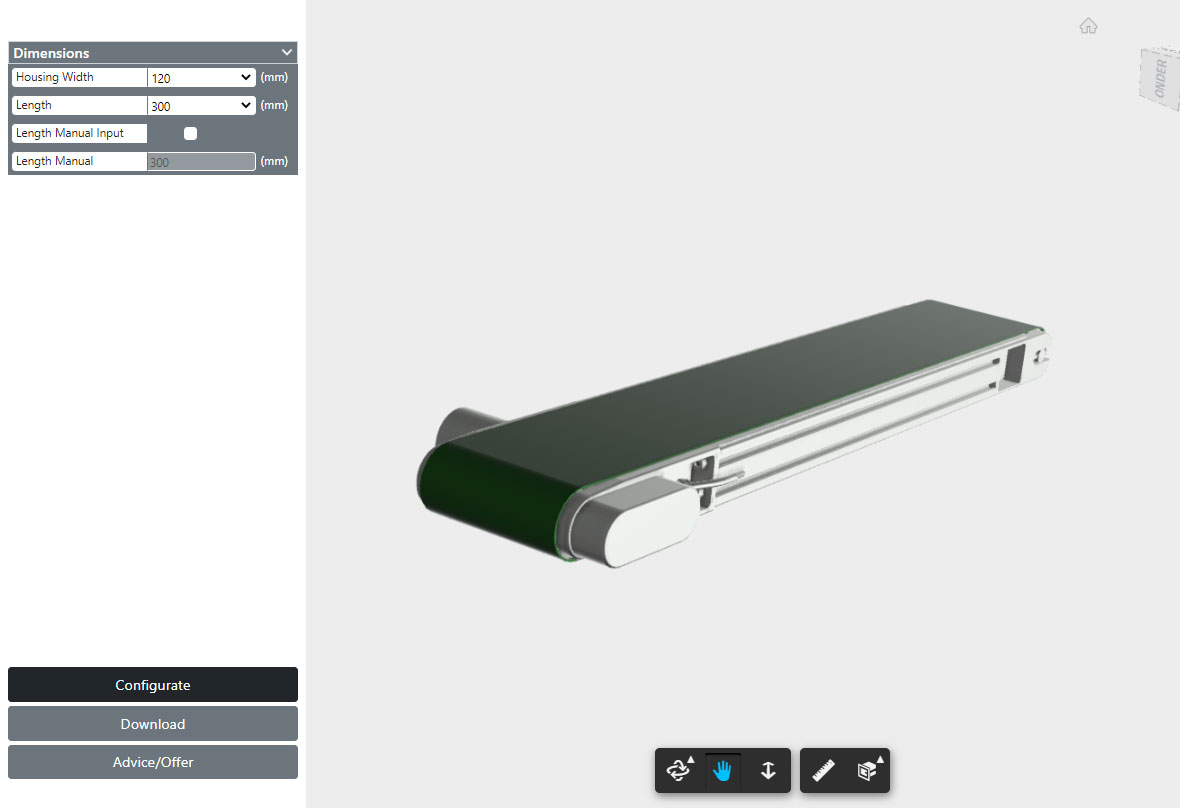

To speed up the design process, most 3D models of the mini-conveyors can be downloaded using the configurator on this website.

- pick & place systems

- orientation & feeding systems

- robotic systems

- assembly systems

- vision systems

To speed up the design process, most 3D models of the mini-conveyors can be downloaded using the configurator on this website.

Online 3D configurator

The BCK configurator aims to quickly configure 3D models of mini belt conveyors and download them to use in your own 3D designs. The 3D models can be downloaded as STEP, SAT or 3D DWG files.

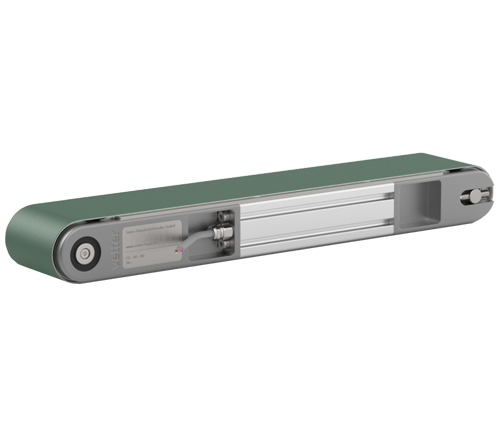

FR-12-20

Small conveyor belt with internal drive

Belt width: 17 mm

Frame width: 20 mm

Frame height: 12 mm

Length (between centres): 100 / 150 / 200 mm

Speed: 1.5 m/min at 2 N belt load

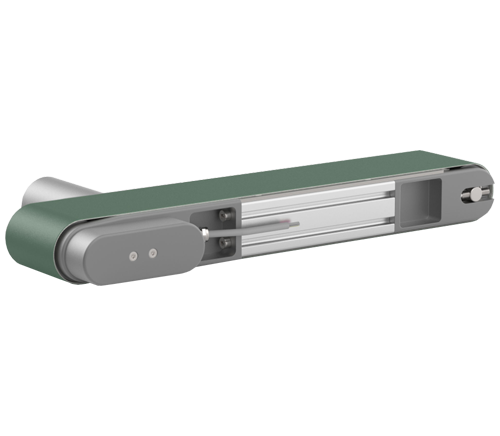

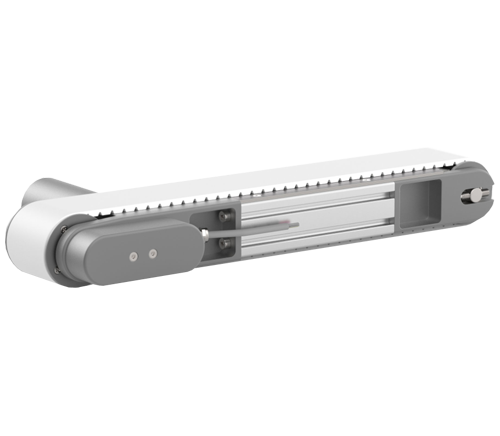

FR-12-20-DL (with light box)

Small conveyor belt with internal drive

Belt width: 17 mm

Frame width: 20 mm

Frame height: 12 mm

Length (between centres): 100 / 150 / 200 mm

Speed: 1.5 m/min at 2 N belt load

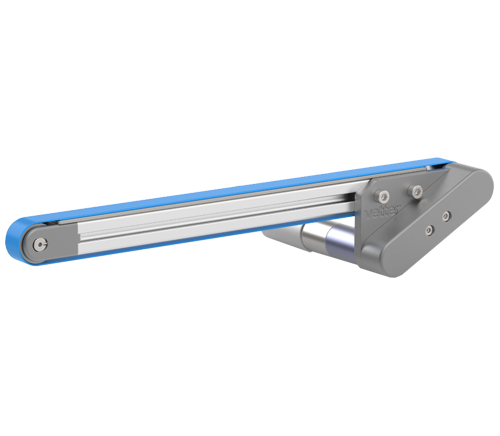

FR-20-40

Small conveyor belt with internal drive

Belt width: 32 mm

Frame width: 40 mm

Frame height: 20 mm

Length (centre-to-centre): 300 - 1,000 mm

Speed:

2 - 8 m/min at 5 N belt load

0.7 - 3 m/min at 15 N belt load

0.7 - 3 m/min at 15 N belt load

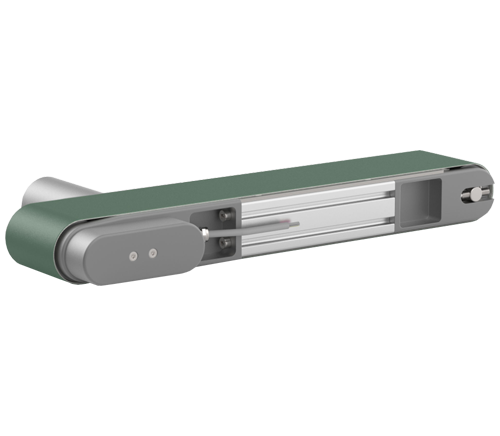

FR-20-40-DL (with light box)

Small conveyor belt with internal drive

Belt width: 32 mm

Frame width: 40 mm

Frame height: 20 mm

Length (centre-to-centre): 350 - 1,000 mm

Speed:

2 - 8 m/min at 5 N belt load

0.7 - 3 m/min at 15 N belt load

0.7 - 3 m/min at 15 N belt load

FR-30-60-200

Small conveyor belt with internal drive

Belt width: 50 mm

Frame width: 60 mm

Frame height: 30 mm

Length (between centres): 200 mm

Speed:

2 - 10 m/min at 20 N belt load

0.5 - 3.5 m/min at 40 N belt load

0.5 - 3.5 m/min at 40 N belt load

FR-30-60

Small conveyor belt with internal drive

Belt width: 50 mm

Frame height: 30 mm

Frame width: 60 mm

Length (centre-to-centre): 300 - 1,200 mm

Speed:

2 - 10 m/min at 20 N belt load

0.5 - 3.5 m/min at 40 N belt load

0.5 - 3.5 m/min at 40 N belt load

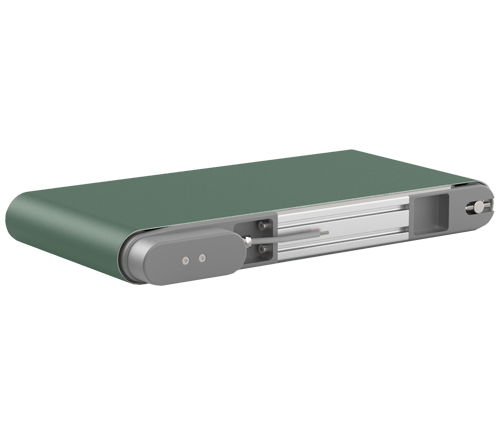

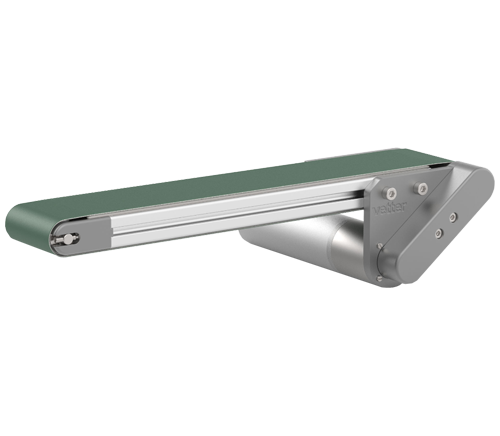

FR-40-80

Small conveyor belt with internal drive

Belt width: 65 mm

Frame width: 80 mm

Frame height: 40 mm

Length (centre-to-centre): 350 - 1,600 mm

Speed:

2 - 10 m/min at 50 N belt load

0.5 - 3 m/min at 100 N belt load

0.5 - 3 m/min at 100 N belt load

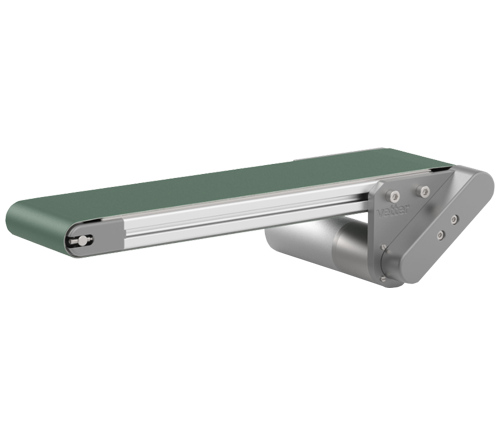

FR-40-120

Small conveyor belt with internal drive

Belt width: 105 mm

Frame width: 120 mm

Frame height: 40 mm

Length (centre-to-centre): 350 - 1,600 mm

Speed:

2 - 10 m/min at 50 N belt load

0.5 - 3 m/min at 100 N belt load

0.5 - 3 m/min at 100 N belt load

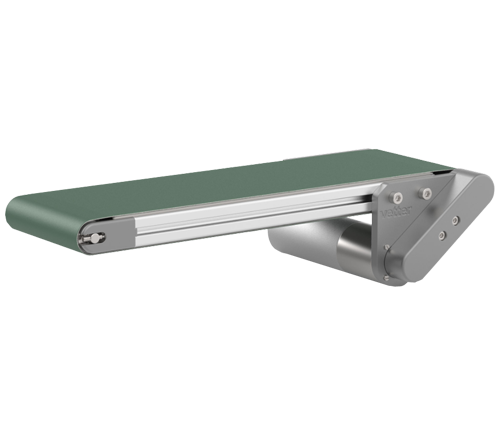

FR-40-160

Small conveyor belt with internal drive

Belt width: 145 mm

Frame width: 160 mm

Frame height: 40 mm

Length (centre-to-centre): 350 - 1,600 mm

Speed:

2 - 10 m/min at 50 N belt load

0.5 - 3 m/min at 100 N belt load

0.5 - 3 m/min at 100 N belt load

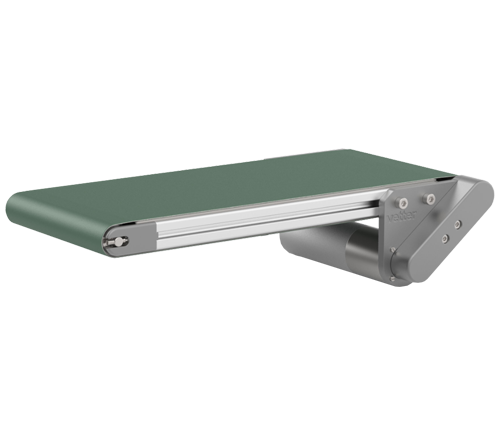

FR-40-200

Small conveyor belt with internal drive

Belt width: 185 mm

Frame width: 200 mm

Frame height: 40 mm

Length (centre-to-centre): 350 - 1,600 mm

Speed:

2 - 10 m/min at 50 N belt load

0.5 - 3 m/min at 100 N belt load

0.5 - 3 m/min at 100 N belt load

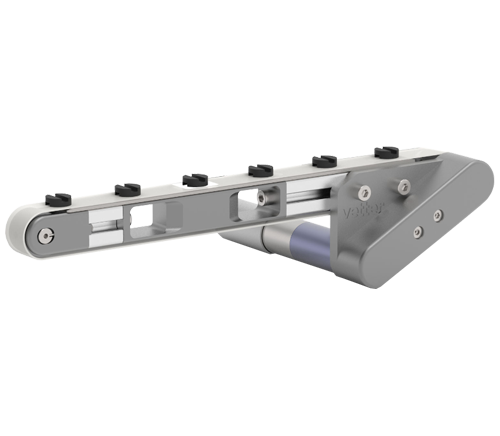

FR-40-80-Q

Small conveyor belt with indirect drive

Belt width: 65 mm

Frame width: 80 mm

Frame height: 40 mm

Length (centre-to-centre): 300 - 1,600 mm

Speed:

5 - 30 m/min at 20 N belt load

4 - 24 m/min at 40 N belt load

1.5 - 10 m/min at 100 N belt load

4 - 24 m/min at 40 N belt load

1.5 - 10 m/min at 100 N belt load

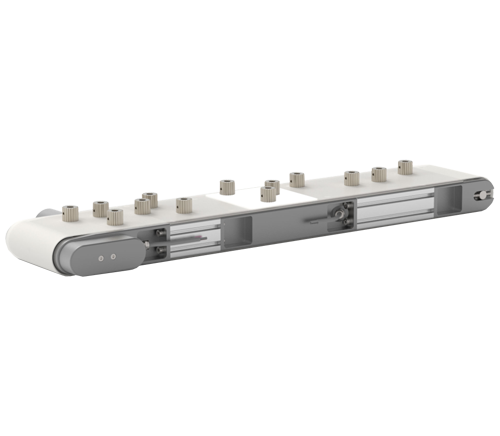

FR-40-80-Q-DL (with light box)

Small conveyor belt with indirect drive

Belt width: 65 mm

Frame width: 80 mm

Length (centre-to-centre): 450 - 1,600 mm

Frame height: 40 mm

Speed:

5 - 30 m/min at 20 N belt load

4 - 24 m/min at 40 N belt load

1.5 - 10 m/min at 100 N belt load

4 - 24 m/min at 40 N belt load

1.5 - 10 m/min at 100 N belt load

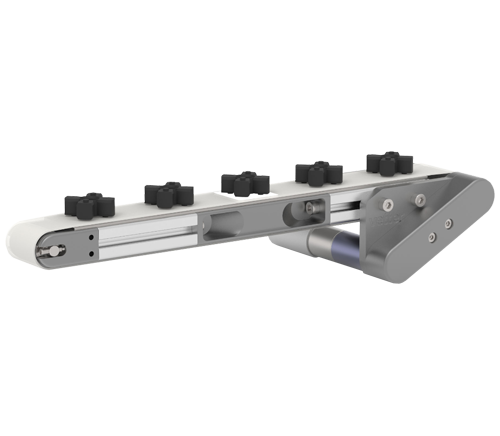

FR-40-120-Q

Small conveyor belt with indirect drive

Belt width: 105 mm

Frame width: 120 mm

Frame height: 40 mm

Length (centre-to-centre): 300 - 1,600 mm

Speed:

5 - 30 m/min at 20 N belt load

4 - 24 m/min at 40 N belt load

1.5 - 10 m/min at 100 N belt load

4 - 24 m/min at 40 N belt load

1.5 - 10 m/min at 100 N belt load

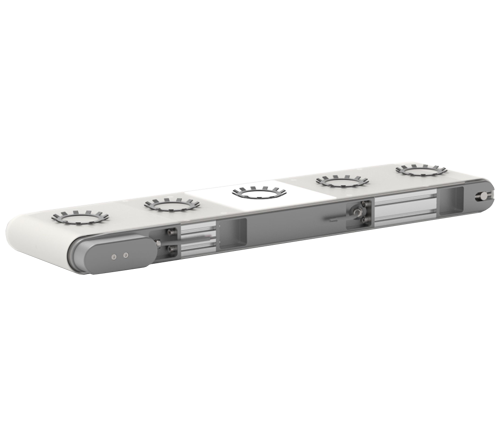

FR-40-120-Q-DL (with light box)

Small conveyor belt with indirect drive

Belt width: 105 mm

Frame width: 120 mm

Frame height: 40 mm

Length (centre-to-centre): 450 - 1,600 mm

Speed:

5 - 30 m/min at 20 N belt load

4 - 24 m/min at 40 N belt load

1.5 - 10 m/min at 100 N belt load

4 - 24 m/min at 40 N belt load

1.5 - 10 m/min at 100 N belt load

FR-40-160-Q

Small conveyor belt with indirect drive

Belt width: 145 mm

Frame width: 160 mm

Frame height: 40 mm

Length (centre-to-centre): 300 - 1,600 mm

Speed:

5 - 30 m/min at 20 N belt load

4 - 24 m/min at 40 N belt load

1.5 - 10 m/min at 100 N belt load

4 - 24 m/min at 40 N belt load

1.5 - 10 m/min at 100 N belt load

FR-40-160-Q-DL (with light box)

Small conveyor belt with indirect drive

Belt width: 145 mm

Frame width: 160 mm

Frame height: 40 mm

Length (between centres): 500 - 1,600 mm

Speed:

5 - 30 m/min at 20 N belt load

4 - 24 m/min at 40 N belt load

1.5 - 10 m/min at 100 N belt load

4 - 24 m/min at 40 N belt load

1.5 - 10 m/min at 100 N belt load

FR-40-200-Q

Small conveyor belt with indirect drive

Belt width: 185 mm

Frame width: 200 mm

Frame height: 40 mm

Length (centre-to-centre): 300 - 1,600 mm

Speed:

5 - 30 m/min at 20 N belt load

4 - 24 m/min at 40 N belt load

1.5 - 10 m/min at 100 N belt load

4 - 24 m/min at 40 N belt load

1.5 - 10 m/min at 100 N belt load

FR-40-200-Q-DL (with light box)

Small conveyor belt with indirect drive

Belt width: 185 mm

Frame width: 200 mm

Frame height: 40 mm

Length (between centres): 600 - 1,600 mm

Speed:

5 - 30 m/min at 20 N belt load

4 - 24 m/min at 40 N belt load

1.5 - 10 m/min at 100 N belt load

4 - 24 m/min at 40 N belt load

1.5 - 10 m/min at 100 N belt load

FR-40-80-Q-P

Small conveyor belt with indirect drive

Belt width: 65 mm

Frame width: 80 mm

Frame height: 40 mm

Length (centre-to-centre): n/a

Speed:

5 - 30 m/min at 20 N belt load

4 - 24 m/min at 40 N belt load

1.5 - 10 m/min at 100 N belt load

4 - 24 m/min at 40 N belt load

1.5 - 10 m/min at 100 N belt load

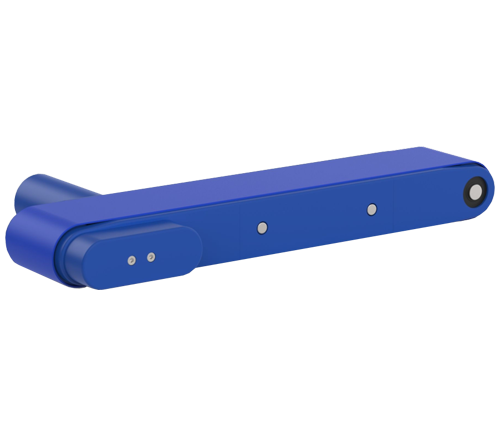

FR-20-20-M

Small conveyor belt with central drive

Belt width: 15 mm

Frame height: 20 mm

Frame width: 20 mm

Length (between centres): 200 - 1,000 mm

Speed: 2 - 40 m/min at 30 N belt load

ZR-40-80

Small conveyor belt with internal drive

Belt width: 50 mm

Frame width: 80 mm

Frame height: 40 mm

Length (centre-to-centre): n/a

Speed:

2 - 10 m/min at 50 N belt load

0.5 - 3 m/min at 100 N belt load

0.5 - 3 m/min at 100 N belt load

ZR-40-80-Q

Small conveyor belt with internal drive

Belt width: 50 mm

Frame width: 80 mm

Frame height: 40 mm

Length (between): n/a

Speed:

5 - 30 m/min at 20 N belt load

4 - 24 m/min at 40 N belt load

1.5 - 10 m/min at 100 N belt load

4 - 24 m/min at 40 N belt load

1.5 - 10 m/min at 100 N belt load

BK-20-20

Small conveyor belt with indirect drive

Belt width: 15 mm

Frame width: 20 mm

Frame height: 20 mm

Length (centre-to-centre): n/a

Speed:

2.5 - 20 m/min at 10 N belt load

0.8 - 6 m/min at 20 N belt load

0.8 - 6 m/min at 20 N belt load

BK-20-20-DL (with light box)

Small conveyor belt with indirect drive

Belt width: 15 mm

Frame width: 20 mm

Frame height: 20 mm

Length (centre-to-centre): n/a

Speed:

2.5 - 20 m/min at 10 N belt load

0.8 - 6 m/min at 20 N belt load

0.8 - 6 m/min at 20 N belt load

BK-20-40

Small conveyor belt with indirect drive

Belt width: 32 mm

Frame width: 40 mm

Frame height: 20 mm

Length (centre-to-centre): n/a

Speed:

2.5 - 20 m/min at 10 N belt load

0.8 - 6 m/min at 20 N belt load

0.8 - 6 m/min at 20 N belt load

BK-20-40-DL (with light box)

Small conveyor belt with indirect drive

Belt width: 32 mm

Frame width: 40 mm

Frame height: 20 mm

Length (centre-to-centre): n/a

Speed:

2.5 - 20 m/min at 10 N belt load

0.8 - 6 m/min at 20 N belt load

0.8 - 6 m/min at 20 N belt load

BK-20-60

Small conveyor belt with indirect drive

Belt width: 52 mm

Frame width: 60 mm

Frame height: 20 mm

Length (centre-to-centre): n/a

Speed:

2 - 15 m/min bij 40 N bandbelasting

0,8 - 5 m/min bij 100 N bandbelasting

0,8 - 5 m/min bij 100 N bandbelasting

BK-20-80

Small conveyor belt with indirect drive

Belt width: 72 mm

Frame width: 80 mm

Frame height: 20 mm

Length (centre-to-centre): n/a

Speed:

2 - 15 m/min at 40 N belt load

0.8 - 5 m/min at 100 N belt load

0.8 - 5 m/min at 100 N belt load

BK-20-100

Small conveyor belt with indirect drive

Belt width: 92 mm

Frame width: 100 mm

Framehoogte: 20 mm

Length (centre-to-centre): n/a

Speed:

2 - 15 m/min at 40 N belt load

0.8 - 5 m/min at 100 N belt load

0.8 - 5 m/min at 100 N belt load

BK-20-120

Small conveyor belt with indirect drive

Belt width: 112 mm

Frame width: 120 mm

Frame height: 20 mm

Length (centre-to-centre): n/a

Speed:

2 - 15 m/min at 40 N belt load

0.8 - 5 m/min at 100 N belt load

0.8 - 5 m/min at 100 N belt load

BK-20-140

Small conveyor belt with indirect drive

Belt width: 132 mm

Frame width: 140 mm

Frame height: 20 mm

Length (centre-to-centre): n/a

Speed:

2 - 15 m/min at 40 N belt load

0.8 - 5 m/min at 100 N belt load

0.8 - 5 m/min at 100 N belt load

BK-20-160

Small conveyor belt with indirect drive

Belt width: 152 mm

Frame width: 160 mm

Frame height: 20 mm

Length (centre-to-centre): n/a

Speed:

2 - 15 m/min at 40 N belt load

0.8 - 5 m/min at 100 N belt load

0.8 - 5 m/min at 100 N belt load

BK-20-180

Small conveyor belt with indirect drive

Belt width: 172 mm

Frame width: 180 mm

Frame height: 20 mm

Length (centre-to-centre): n/a

Speed:

2 - 15 m/min at 40 N belt load

0.8 - 5 m/min at 100 N belt load

0.8 - 5 m/min at 100 N belt load

BK-20-200

Small conveyor belt with indirect drive

Belt width: 192 mm

frame width: 200 mm

Frame height: 20 mm

Length (centre-to-centre): n/a

Speed:

2 - 15 m/min at 40 N belt load

0.8 - 5 m/min at 100 N belt load

0.8 - 5 m/min at 100 N belt load

BK-30-60

Small conveyor belt with indirect drive

Belt width: 50 mm

Frame width: 60 mm

Frame height: 30 mm

Length (centre-to-centre): n/a

Speed:

3 - 20 m/min at 30 N belt load

1 - 7 m/min at 100 N belt load

1 - 7 m/min at 100 N belt load

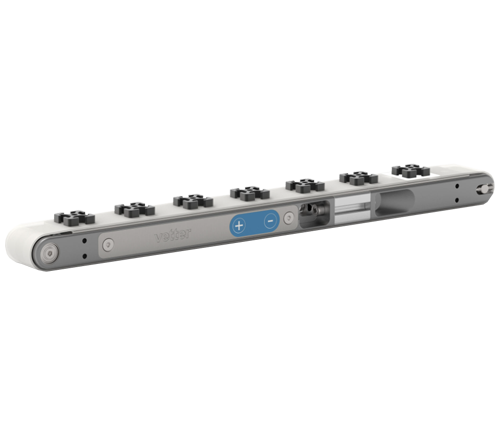

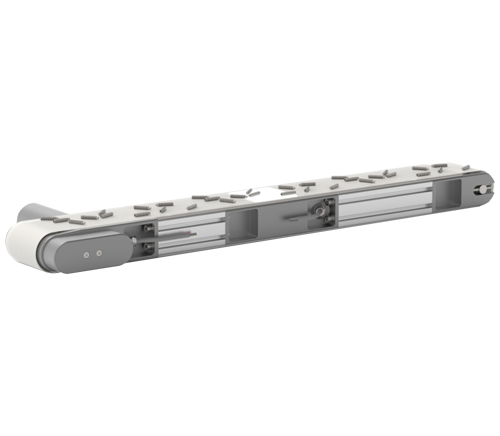

Special Mini-conveyors

The mini-conveyor is a modular product. Therefore, it is also possible to produce special versions of mini-conveyors. We would be happy to advise you in a personal conversation. Please contact us for more information or to discuss your application.