Gravity roller conveyor type RC50G

If it is not a humid environment or stainless steel is not required, an aluminium gravity roller conveyor can be applied. The possibilities of aluminium roller conveyors are endless. The most frequently applied gravity roller conveyor is a gravity roller conveyor type RC50G.

Terms of application

The RC50G gravity roller conveyor is the most versatile non-driven roller conveyor in its class. This versatile gravity roller conveyor has many variants and to apply the RC50G roller conveyor, your application should meet the following conditions to ensure a long service life:

Environment: Dry and clean to lightly soiled

Load: Max. 150 kg/meter

Speed: n/a

Roller diameter: Ø20 / Ø30 / Ø50 mm

The basic frame of the driven roller conveyors RC50G consists of an aluminium profile designed from the experience of our users.The T-slots in the profiles are designed in such a way that standard fasteners can be tilted in. This means that various components (such as side guides or photocells) can easily be fitted to the frame by the customer after delivery. The T-slots can also be sealed later.

Partly because of the modular concept, the possibilities in terms of dimensions, pitch, roller diameter, roller type (plastic, steel, aluminium and stainless steel), frames and side guides are endless.

Technical specifications

- Basic: Aluminium frame with integrated cable ducts on both sides

- Curve modules: 30°, 45°, 60°, 90° and 180°

- Roller width: approx. 100 - 1,200 mm (very fast delivery: 410 - 510 - 610 mm)

- Roller diameter: 50 mm (20 mm / 30 mm)

- Roller pitch: 55 - 75 - 100 - 125 mm

- System length: unlimited

- Frame performed with high or low profile

- Galvanised steel, plastic or stainless steel rollers

- Roller tracks instead of rollers

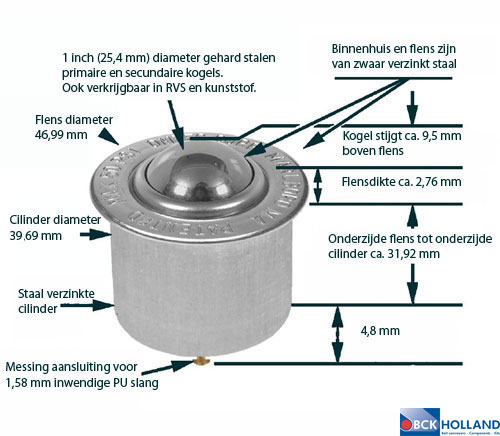

- (Pneumatic) Ball pots instead of rollers

- Folding section

- Undercarriage

- Adjustable side guide

- End stop

Roller tracks instead of rollers

Ball transfer unit instead of rollers

- transferring products at right angles

- handling heavy products (the product can be moved in any direction)

- as an aid for manually moving or positioning products

- saving of labour hours

- movement possible in X and Y directions

- contributes to a continuous process

- system is custom-made.

Pneumatic ball transfer units and positioning pads

Standard (fixed) ball transfer units are often very convenient, but by applying pneumatic ball transfer units and pneumatic positioning pads, a very safe and ergonomic workplace can be created quite easily. These components are often used in combination with roller conveyors, work tables and/or lifting tables. BCK Holland can supply these complete with an air supply unit and switch(s).

The load capacity of the pneumatic ball transfer unit is approximately 23 kg, but due to various factors, the pneumatic ball transfer unit is best applied when a load capacity of between 2.3 and 13.6 kg per ball transfer unit is required. The load capacity of the pneumatic positioning pad is somewhat lower, at around 9 kg per pad. A pneumatic ball pot or positioning pad consumes very little air. Approximately 0.0000108 cubic metres are consumed per cycle.