Industries

5. Zero pressure buffering of letterbox packages

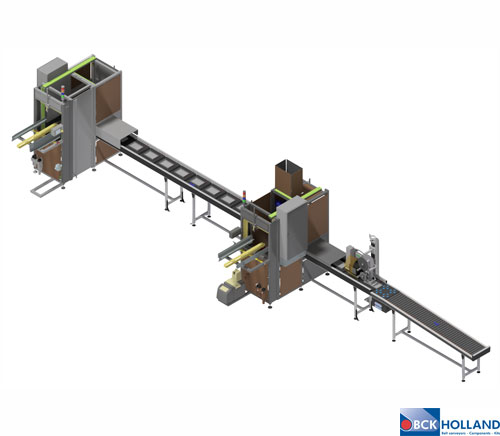

Our client has developed a packaging line for letterbox packages. An innovative system put together with Dutch partners. Specially developed for the automatic packing of 900 parcels per hour, destined for letterbox delivery.

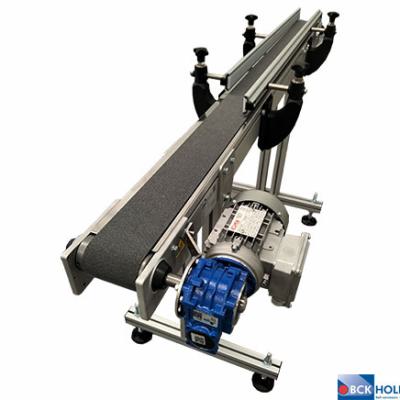

BCK Holland is the partner for the transport systems. Our RD50 ZPA (Zero Pressure Accumulation) roller conveyor creates a perfect transport of letterbox packages between the carton erector, carton sealer and labelling machine in the delivered line from system integrator.

The operation of the line explained in steps.

- Station 1 is a tray erector, which places boxes with a completely flat bottom on the conveyor belt

- At the next station, we use an inkjet printer to print a unique number on the box (LPN), which is linked to the order and read and checked during the process.

- This unique LPN code is read at the next station to record the position of the order and enter it into the system

- Between the station where the trays are filled we also find the HMI containing the User Interface. Here you can find information about the track speed, the job running and we show disturbances

- The camera systems at station 5 check the products and can read the EAN code of the product or the barcode of a packing note, for example.

- Station 6 takes care of closing the boxes by placing and sticking a lid

- After closing the boxes, the shipping label is automatically applied and the barcodes are checked again

- The buffer conveyor ensures there is time to take down and sort the packed shipments. Several exits are possible here

Figure 1:

BCK Holland B.V.

Spuiweg 24

5145 NE Waalwijk

The Netherlands

[T] +31 (0)416 673880

sales@bckholland.com

www.bckholland.com

CoC: 18076783

VAT nr: NL813897075B01