At a time when sustainability is becoming increasingly prominent, making conveyor systems more sustainable is a crucial step towards more environmentally friendly operations. BCK Holland, always a partner that thinks along with the customer, plays an active role in this by offering sustainable conveyor solutions that not only lower the Total Cost of Ownership, but also reduce the ecological footprint of companies.

1. Energy efficiency as a Driving Force

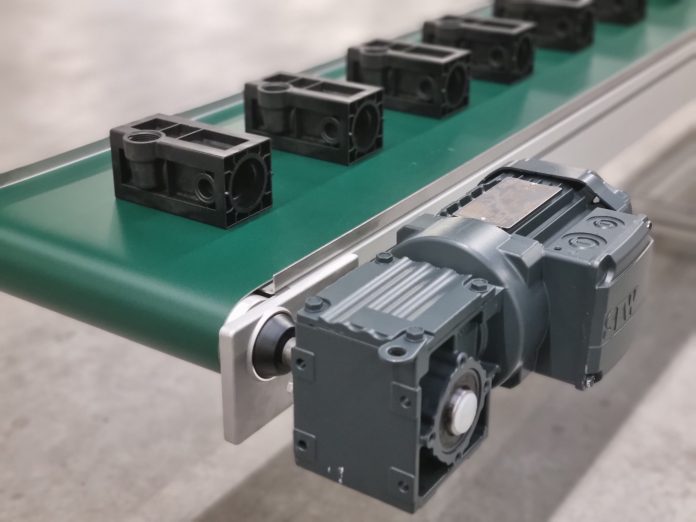

Energy efficiency is central to making conveyor systems sustainable. The use of advanced gearmotors and control systems, such as variable speed drives, optimises energy consumption by adjusting the speed of conveyors to the load. The use of flexible belt material with a low coefficient of friction also contributes to a more energy-efficient process.

2. Conscious Choice of Materials for a Long-lasting Impact

The choice of materials determines the durability of conveyor systems. Materials with a longer lifespan and easy recyclability not only reduce environmental impact but also contribute to a circular economy. BCK Holland recommends materials that are produced in an environmentally friendly way.

3. Maintenance, Monitoring and Prevention

Regular maintenance minimises wear and ensures that conveyor systems continue to operate efficiently. Advanced monitoring systems detect early signs of problems, preventing unnecessary downtime. A proactive approach extends service life and reduces the need for replacement.

4. Recycling as a Priority

Reducing waste and extending the life of materials are achieved through smart material choices, such as using recyclable PU belt materials without fabric.

5. Smart Drive Technologies for Efficiency

Energy-efficient drive technologies, such as direct drive systems and 24V motor rollers that pump back energy during braking, reduce losses in efficiency. A thoughtful drive system results in less friction and lower energy costs.

6. Automation and Optimisation for Maximum Efficiency

Automation and optimisation systems minimise unnecessary movements, optimise load and speed, and thus increase the overall efficiency of the transport process.

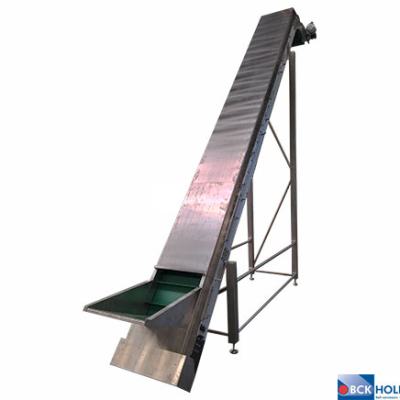

7. Economical Design for Customisation

An economical design, where conveyor length is optimised for specific needs, maximises efficiency and minimises waste.

8. Reusability and Disassembly for Flexibility

Conveyor belts are designed with reusability and disassembly in mind, making maintenance and replacement easier and reducing waste.

BCK Holland and its partners strive to work with customers to complete the total picture of sustainability. This joint effort not only improves the efficiency of transport systems, but also significantly reduces the impact on the environment.